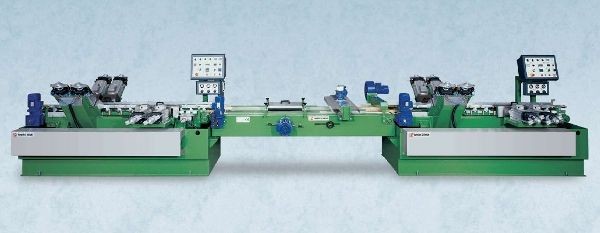

BBV/20-60 G

The machine allows the processing (chamfering) of granite tiles through abrasive plates moved by spindle-motors. The structure is mainly composed of a tubolar tank made of electro-welded steel and of two lateral milled supports, spindle holders. They are moved by two screws controlled by a ratio-motor. Two big ground, chromium plated rods keep them in the correct position. All the mechanical guides can be set to adjust the clearance. The water feeding pipes are adequately dimensioned for a good cooling of the abrasive wheels. A belt motorized roller table (turning unit), allows to rotate the tiles till 90° and supplements the two chamfering machines. It is possible to lift the whole structure by means of lifting hooks fixed on the three machines which compose the line (input chamfering unit, turning unit and output chamfering unit). The non-deformability of the machine is guaranteed during the lifting operation. Green epoxy bi-component painting RAL 6011. Some backlighted signallers have been installed on the electric board to indicate the abrasive change. The panels are painted with epoxy enamel RAL 7032, thickness of steel mm 15/10. The feeding is composed of a magnetothermal switch with door locking to avoid the opening of the electric board with tension.

8 chamfering units – motors kW 2,2

4 calibrating units – motors kW 2,7

1 tiles turning unit – motor kW 0,18

1 unit for lower grooving

for n. 2 discs – motor kW 2,2

- ventilator motor n 1

- ventilator motor power kW 0,55

- open-close motor n 2

- open-close motor power kW 0,37

- displayed opening-closing

- abrasive plates for chamfering diameter mm 130

- plates for calibrating diameter

(diamond tools) mm 140

- discs for lower grooving diameter mm 250

- shaft for lower grooving diameter mm 50

- n. 2 motors conveyor units each powered by kW 0,55

- n. 1 motor turning unit belt powered by kW 0,22

- useful work dimensions mm 200/610

- workable material thickness mm min. 7 - max. 30

- control of abrasive consumption with light signal

- displayed belt forwarding speed

- belt speed electronic adjustment

- water consumption /min 60

- air consumption at 6 bar l/min 30

- total installed power kW 33