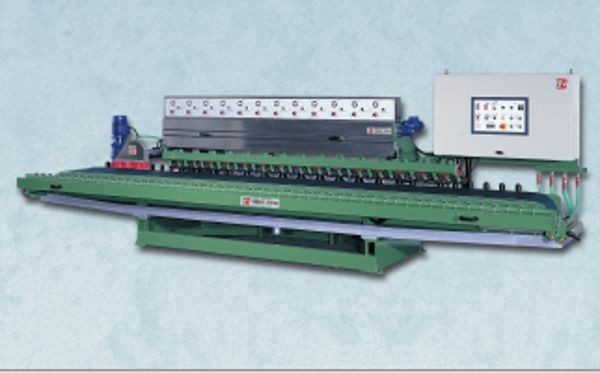

CBV/960 G

Side polishing machine mod. CBV/960 G allows the processing (polishing) of marble and granite vertical sides of different thickness by means of abrasive wheels moved by spindle-motors. It is also possible to chamfer the lower and upper edges through spindles inclined till 45° compared with the side of the strips. The machine is basicly composed of two parts: a carpentry, spindle holder structure, and a planed steel table, where the conveyor belt is installed. The structure is welded and planed and is produced following the new technical concepts, to guarantee accuracy of processing, absence of vibration and high stability. The pressure roller table has rubber rolls. It is very easy to replace them in case of wear. The roller table is moved by a ratio-motor operated by an electric control installed on the electric board. All the water feeding pipes are dimensioned to guarantee a good inflow for the perfect dressing of the abrasive wheels. Some limit switches installed on the pressure roller table, or a PLC (optional) guarantee the spindle outlet during the different phases of processing. It is also possible to adjust their position to anticipate or delay the abrasive wheel outlet. The machine has two hooks to lift the whole structure. The non-deformability of the components is guaranteed during the unloading operation. The electric board is built with steel plate, thickness 15/10, painted with RAL 7032. Its degree of protection is IP 55. An insulated transformer for 380V network voltage and output 48V is installed inside the electric board for all the control bodies to guarantee the safety of the operator. All the motor protective devices (fuses, magnetothermics and thermal relays) are dimensioned for each single motor to intervene in case of anomaly. Some emergency push buttons are installed in several parts of the machine to totally stop it in case of error of the operator and to assure his safeguard. They are built in such a way that, after being pushed, they keep this position. Restore them to start the machine again.

9 frontal polishing units

2 top edge polishing units

1 bottom edge polishing unit

- maximum width mm 600

- workable material thickness mm 60

- plates carrying abrasives diameter mm 130

- polishing unit motor power kW 1,1

- belt forwarding motor power kW 1,1

- up-down pressure roller table motor power kW 0,18

- material presence computerization

- belt forwarding speed m/min 0,25-1,3

- water consumption l/min 90

- air consumption at 6 bar l/min 35

- total installed power kW 14,5

adjustable blade cut unit

- motor power kW 3

- disc diameter mm 250

- shaft diameter mm 50

drip unit

- motor power kW 3

- disc diameter mm 300

- shaft diameter mm 50

slab supporting roller table and lateral pressure

- revolving till 90°