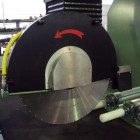

IBV/600 M1-P

This machine enables to square the first and final parts of big thickness strips of Marble and Granite, and also the cut at programmable measure, and the possibility to step-cut (suggested for hard materials). The grinded table with belt is fixed on the structure made of electro-welded steel. The table carries a special rubber belt and it is resistant to wear. A special anticorrosive treatment is effected. The switch board is made of sheet steel, thickness 15/10 mm, painted with RAL 7032 paint, IP 55 protection level. The supplying unit is composed by a magnetothermic switch with shutter locking to avoid the opening of the switch board with tension. It can be restored after opening the shutter, in case of maintenance.

- disc diameter max mm 750

- shaft diameter for disc fixing mm 50

- cutting unit motor power kW 15

- cutting unit forwarding motor power kW 0,55

- cutting speed electronic adjustment by inverter

- belt forwarding motor power kW 1,5

- electronic adjustment of belt speed

- useful cutting width mm 600 (mm 800 on request)

- useful thickness of working marble mm 250 (for both marble and Granite)

- disc motor number of revolutions marble-granite rpm 1450

- water consumption l/min 30

- total installed power kW 17

- unit of cut predisposed for multiple passings

programmable on touch screen, with the possibility

to set n. 9 measures repeatable individually

Optional: